How does picking with Pickware work in Shopware 6?

You want to make your online store more efficient and optimize your order picking? Then you're in the right place! In this blog post, we'll show you useful tips and tricks on how to simplify and speed up your order picking with Pickware in Shopware 6. Let's work together to make your shop more successful!

Anyone who runs a shipping business knows the challenges with order picking. Manual tasks, packing lists, and the picking process itself can make the tasks quite lengthy.

Especially for modern online retailers, a smooth operational flow and easy integration of backend systems are crucial. In this respect, the combination of Pickware and Shopware 6 has proven to be extremely valuable.

Furthermore, particularly for those who get overwhelmed easily, a high volume of orders can quickly lead to one or more numerical errors.

By the way, there are often untapped potentials here, as there are also ways to save resources. Besides this point, there are various methods of order picking, each with its own advantages and disadvantages.

But how do you best optimize all this, and what solutions does Shopware 6 offer in this regard? In this article, you will learn everything you need to know for your order picking process. Let's start with the different picking strategies.

Let's start with this: What is pickware anyway?

Pickware is an enterprise resource planning (ERP) system designed specifically for the e-commerce sector. It provides online retailers with a variety of tools that help manage inventory, orders, customer relationships and other critical business areas.

Pick yourself happy: Why picking with Pickware in Shopware 6 is a win-win for you.

Order picking can be a tedious and time-consuming task. But with Pickware in Shopware 6, this process becomes simpler than ever. You'll soon find that working with Pickware not only saves time but also optimizes your inventory management and processes.

The intuitive interface makes getting started easy and allows you to focus on the essentials: assembling your customers' orders.By speeding up the shipping process, you'll make your customers happier and thus retain them in the long run. The best part is that you can benefit from these advantages without much effort. With Pickware in Shopware 6, you maximize your warehouse's potential and increase your company's efficiency.

If you want to benefit from Pickware quickly and easily, you've made the right choice. With Pickware, you can optimize your order picking in Shopware 6 and streamline your inventory management and processes. The intuitive operation of Pickware makes it easy to get started and allows you to find your way around quickly.Through efficient order picking, you achieve faster shipping and thus retain your customers for the long term.

So, leverage the benefits of Pickware to strengthen your business and satisfy your customers.With Pickware, you'll quickly realize how simple it can be to improve your warehouse management and optimize your processes - try it out and experience the difference!

How to optimize your inventory management and processes with Pickware

If you want to optimize your inventory management and processes, you should definitely use Pickware. With Pickware, for example, you can automatically forward orders to the warehouse and create labels for shipping directly from the system. This saves you time and minimizes sources of error.

Inventory is also child's play with Pickware, as you can view the current stock level at any time. Especially practical: The software can be seamlessly integrated into Shopware 6 and is intuitive to use. This makes it easy to get started and you can quickly benefit from the advantages.

Another plus point: By processing your orders quickly, you can make your customers happier and stand out from the competition. With Pickware, you not only have more fun picking, but also more satisfied customers and a better overview of your warehouse - what more could you want?

Okay. But why does Pickware's intuitive operation make it easier to get started?

If you choose to use Pickware for order picking in Shopware 6, you'll quickly see why its intuitive interface is a significant advantage. The software is designed so that you can find your way around quickly and get started without a lengthy training period.

Even for employees who are new to the company or have no previous experience in order picking, the operation of Pickware is easy to learn. This saves time and costs in training new staff.

Moreover, the intuitive interface also minimizes the risk of errors during the picking process. You'll find that you can work faster and more efficiently, giving you more time for other essential tasks. With Pickware, everyone can effortlessly get started with order picking! Yes, even your future new employees!

Picking strategies

Although picking itself has nothing to do with your e-commerce business but knowing the different strategies is important for your success. After all, choosing the right strategy can save you time and money. There are three types of picking.

The collective picking means the collection of several orders and a subsequent collective picking of these. In this case, the "picking" of the products is started and only then each product is assigned to the respective order.

Individual order picking is very time-consuming. However, this method is particularly useful for large orders, as fewer errors occur here due to this method.

Roll picking is the last picking strategy. This is a mixture of the two previously mentioned. Several orders are taken directly to the warehouse and packed into boxes at the same time. In this case, one box is one order. This method is one of the most time-saving, because it eliminates some walking distances.

With the Pickware tool you have the possibility to select such strategies in advance and, for example, to have the suitable paths displayed directly. Through If, then functional you also have the possibility to combine different strategies. So let's start directly with more information about Pickware in the next paragraph.

Pickware WMS for Shopware 6

With a WMS (Warehouse Management System) you have the possibility to administratively manage your inventories and additionally to overview your warehouse and shipping processes.

By the way, mobile barcode scanners are a particularly smart option. Through these, you can easily scan the packed goods, your stock, from the warehouse to keep up to date. And exactly these possibilities are offered by Pickware for your Shopware 6 Store.

By the way, Pickware offers you more than just this one advantage. Pickware also saves you a lot of time. Through automatically generated packing lists, Pickware also recognizes when you scan in the wrong product. This avoids packing errors.

How exactly Pickware works?

Well, sounds tempting, doesn't it? But surely you need some more information before you decide to use this WMS system. That's why we explain below how Pickware is actually handled.

1. Choose order

If you use Pickware's WMS system, then you also have their mobile scanner. On this scanner you can see all open orders.

You know how it is: an order comes in and it was ordered by express. So it is very time-critical and more important than other, older orders. Pickware does not ignore this point either.

On the scanner, you can see which order you should process first by sorting by relevance. We think this is a super handy feature.

2. Picking

The digital packing list in Pickware saves you valuable time. You can see at a glance which products have been ordered and can pick them up specifically. In addition, the direct barcode scanner helps you to immediately notice if you have packed the wrong product.

So if you happen to scan the wrong product, you will be notified about it directly.

By the way, another cool feature of Pickware: You can specify routes to the individual products. This means: No more long searches for the right products and additionally smart walking suggestions to always choose the shortest way.

We would particularly like to highlight the suggestions for route optimization at this point. After all, large, confusing warehouses and new employees are often the culprits for a lot of wasted time. This is where this function helps significantly.

By the way, here would also be a good point to think about the right storage space system. Be sure to analyze your storage space and make the best use of it. An example of this can be to place products that are not frequently needed in rather impractical places, while frequently ordered products are very easily accessible.

A distinction is made between dynamic and static warehousing and a combination of both methods. Further down in this article, we explain the individual inventory methods.

3. Prepare for shipment

Everything ready so far? Congratulations! Now you can easily print all documents. Yes, that's right. All documents like delivery bill, shipping label and invoice will be created automatically, you just have to press print and attach them to your package.

So remember: Here, too, you save time. Because the manual comparison, the order with the associated papers and the printing normally costs a lot of time.

4. Ready!

Woohoo! 🥳 All done and packed. Now take the package to the shipping company and use the mobile scanner to scan the shipping label.

Scanning the shipping label notifies the customer that the package is on its way to the shipping carrier. All other important information is now transmitted as well. This includes the tracking link, for live tracking of the order, and the shipping confirmation. Fully automatically, of course.

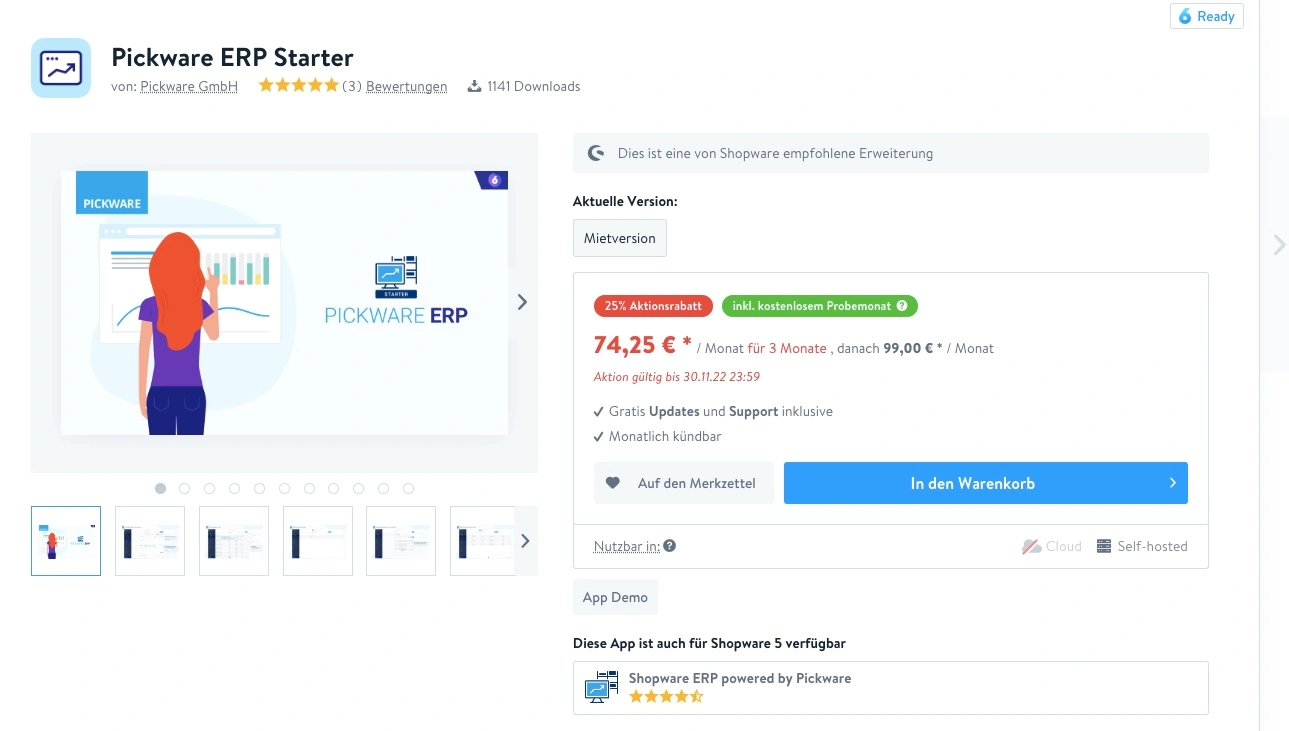

What we have not mentioned so far: To use Pickware WMS, you need Pickware ERP. You can download Pickware ERP from the Shopware Shop. Pickware WMS, on the other hand, can be purchased directly from the Pickware homepage.

Pickware ERP Starter for Shopware 6

Pickware ERP Starter for Shopware 6

The methods of storage

Dynamic inventory management is characterized by flexibility and adaptability. With this method, storage space is allocated based on availability and need, which means items are not consistently located in the same spot. It's ideal for companies that frequently introduce new products or whose inventory often varies. However, an efficient inventory management system is crucial with this approach. Only through a robust software solution can the clarity and accessibility of goods be ensured.

Static inventory management, on the other hand, relies on continuity and structure. In this system, each item is given a fixed storage location where it is always found. This simplifies the storage process and minimizes errors from constant relocations. Companies with a stable and relatively unchanging assortment benefit from this as they always know where a particular product is located.

In reality, many companies adopt a hybrid of both inventory management methods. Decisions are made on a case-by-case basis, determining which approach is most sensible for which product or product group. This way, companies can leverage the advantages of both systems, acting flexibly or structuredly depending on the business needs.

Conclusion on picking with Pickware

Order picking can be quite straightforward and function without any confusion. Pickware presents a unique solution for Shopware 6 in this regard.Even large companies, or especially them, can greatly benefit from Pickware.

Through intelligent route optimization, automatic printing and sending of necessary documents, and the "simple" order picking process, a lot of time is saved and mistakes are avoided.Are you still looking for the right WMS system for your company? - Maybe ask Pickware and give it a try! Honestly, Pickware offers you an optimal solution in Shopware 6 to enhance your processes.

Thanks to the intuitive user interface and easy integration into your system, you can quickly benefit from its advantages and make your inventory management more efficient. Your customers will be happier with faster shipping and thus remain loyal to you in the long run.

P.S: Are you still pondering whether Shopware is the right e-commerce software for you? Then read our article about it here.

Ready for your E-commerce success?

As Shopware agency, we help you create your high-turnover & individual online store and promote it with ads and SEO.